1 Year of Mosul Dam

A lot has been said and written about the extraordinary experience of the Mosul Dam Project. After almost one year from the mobilization of the first Trevi colleagues, it is worth drawing the results of what has been done so far. At the same time it is useful to wonder whether and how this journey is changing us.

The beginning of the adventure

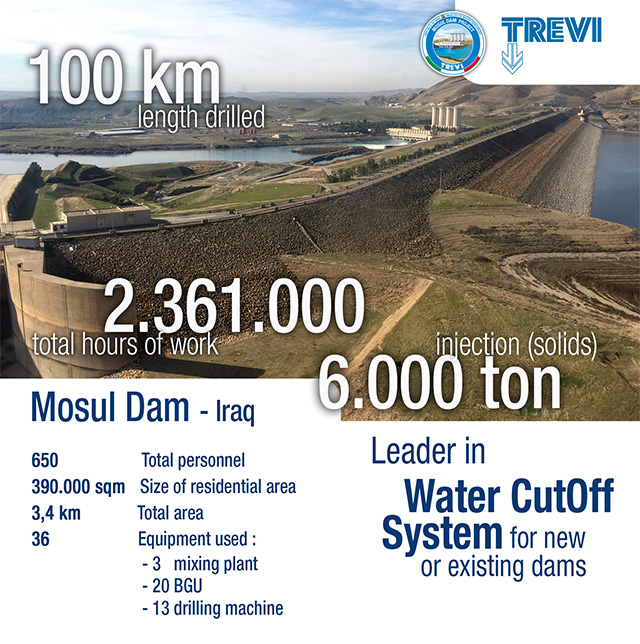

In August 2016, 10 resources were available on site. Mainly managerial profiles sent to identify logistical and operational priorities and to set up the ground for a much broader group of qualified personnel. Today, the project is supported by a staff of about 650 people, including technicians and staff members: Iraqi colleagues, Italians and many other countries, for a total of 11 different nationalities. This increase was possible only thanks to the coordination of all functions, as well as the construction of a residential area of 390,000 square meters, which is about 55 football pitches!

From an operational point of view, the beginning of the activities for the Mosul Dam Project took place together with the modernization of many existing plants. In many cases, a complete dismantling and remodeling of existing structures had to be carried out. To give concrete references, only for the gallery it has been performed the installation of about 250 km of electric cable, 20 km of tubes for grout mix, bentonite, water, concrete and dewatering system, and 2.5 km of fiber optic cable.

The Dam today

The logistical and environmental challenges and the particular hostility of the work area (we want to remind that many of the activities are carried out in a gallery of the average width of 3 mt), as well as rigorous security measures, have not stopped the work of our technicians. As of today, the Mosul Dam has 3 external mixing plants, 20 Batching Grouting Units (BGU) and 13 drilling machines operating 24 hours under the monitoring and guidance of one of the most technologically advanced technical department available in the construction industry. The total area involved is 3.4 km.

Solid injections reached the record quantity of 6,000 tons. The perforated length has been 100 km. A distance greater than the one separating Bologna from Cesena. For the first time, an entirely automated injecting management system was used. This system was specifically designed for Trevi. Underwater activities have been completed successfully. The general safe conditions of the Dam allowed the water to rise again at record levels of 2005, and to reopen the spillway after 12 years from the last opening.

The construction of the residential area is about to be completed, but already has basic facilities (2 canteens, 2 gyms, 1 bar, 1 pizzeria, 1,100 beds, 17 office buildings) to accommodate over 1,000 civilians and military personnel. A largely successful experiment of sharing an area between Trevi personnel and Armed Forces (about 500 soldiers). Everything is done in respect of the highest standards of Safety at Work, having the primary interest in personal health.

It is also useful to recall the close co-ordination with the US Construction Corps of Engineers (USACE), to satisfy the growing demands of our client, the Iraqi Ministry of Water Resources.

Last but not least, the work of Trevi has more than once received the open recognition of the Prime Minister of the Republic of Iraq.

The Trevi of tomorrow

The experience of this unique project allows Trevi to lay the foundations for the future. Actually, the Mosul Dam was not a project, but the set of 6 different projects in a very short time span: the construction of the residential area; the construction of new office buildings and the new warehouse in Dam area; the modernization of infrastructures inside the gallery; the installation of the telecommunications system (c.d. CIS); underwater activities of the Bottom Outlet; Drilling and Grouting.

The role of "lead contractor" in managing these 6 parallel projects allows Trevi to gain solid experience in medium-to-large projects as well as structured sub-contracts management. A new generation of technicians and employees is growing, supported by the experience of long-time staff.

Trevi must have the capability to capitalize on this experience, aiming to further structure its internal processes by following even more the international best practices. The Mosul Dam, in addition to being a successful project for the company, can become a laboratory in which to sprout new techniques and new operating and management models. And as a result, it can play a key role in the growth of the new Trevi resources for the future.