Cased Augered/Secant Piles

The CAP (Cased Auger Piles) technology consists in drilling separate piles by means of a continuous flight auger coaxial to an external casing.

The same technique can also be used to drill secant piles; in this case it is named CSP (Cased Secant Piles). The auger and casing are operated by two independent rotary tables which mutually counterrotate and travel along the mast of the drilling rig.

This technique allows to drill piles of a nominal diameter of 600 to 1200 mm.

The max depth achievable by the casing is 21 m, whereas the max depth technically admitted by the auger is roughly 30 m (depending on drilling diameter and tool).

The rotary tables travel along the mast independently: as a result it is possible to penetrate the auger and casing to different dephts, depending on soil type. Generally speaking, in case of cohesive or fine non-cohesive soils, the auger bit and the casing shoe are maintained at the same level; however, in the event of coarse non-cohesive materials the auger penetrates more deeply than the shoe in order to lighten the soil and make it easier to move it within the casing. In case of rocky soil, the casing advances as a core barrel, whereas the auger bit fitted with teeth suitable for rocks breaks up the “core” created by the casing. Both the auger bit and casing shoe are fitted with teeth, depending on the type of material to drill.

Technology

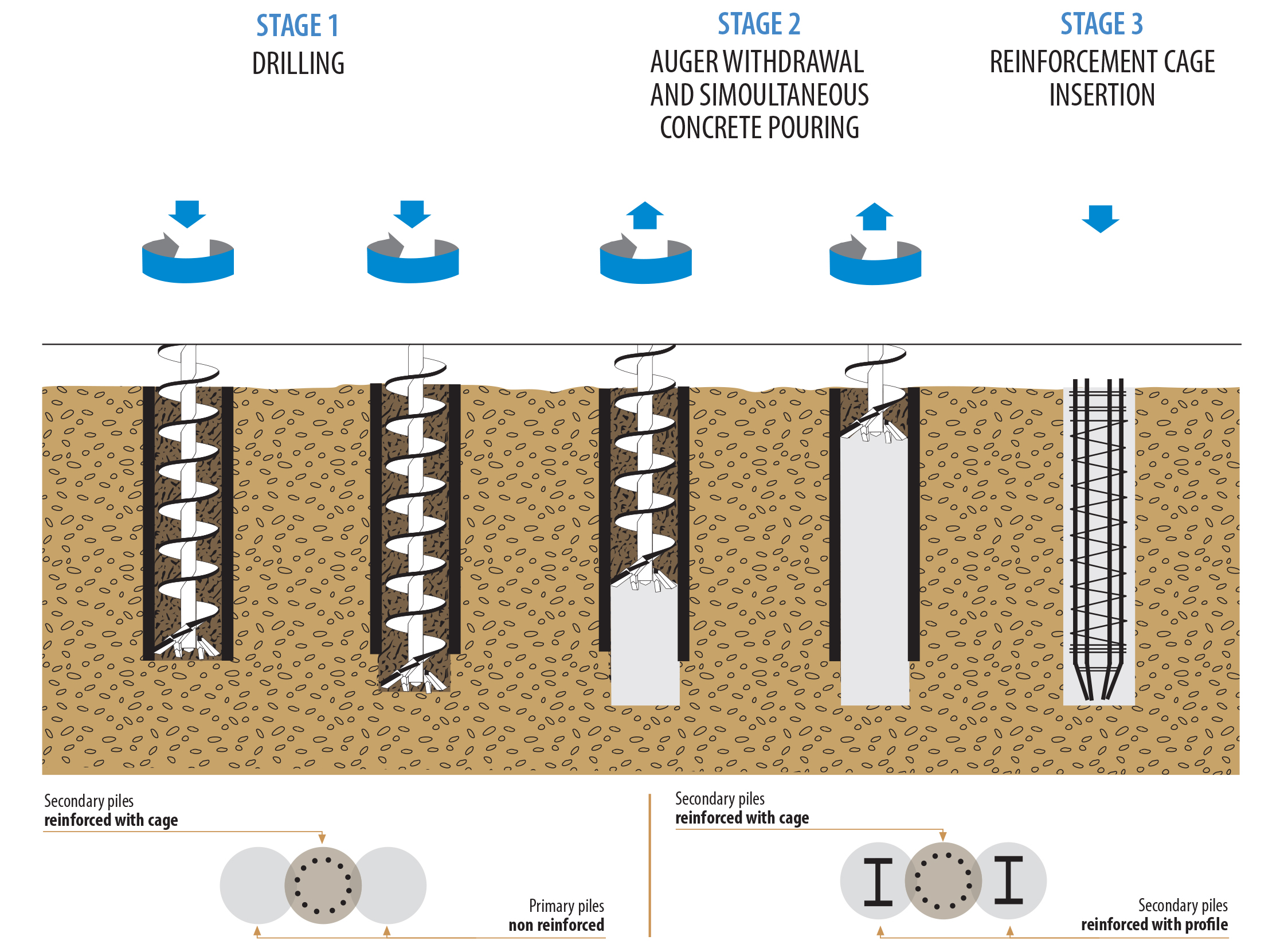

The operating sequence consists in driving the auger and casing simultaneously. Once the max casing penetration depth has been reached, it is possible to continue to drill to the design depth using the continuous flight auger only. Then the auger filled with soil is extracted and at the same time concrete is pumped through the central hollow stem to fill the gap left by the drilled soil up to the work level. The casing is usually extracted once the auger has been lifted by a few metres inside it. Once auger and casing have been fully withdrawn, the reinforcement cage is positioned through the freshly pumped concrete.