Diaphragm Walls - Hydromill

The excavation of diaphragm walls with hydromill allows the construction of panels with max deviation from the vertical of about 0.3-0.5%, at depths beyond 200 m. With this technology, it is possible to excavate diaphragm walls in soil layers and bedrocks with compressive strength – UCS – up to 60-80 MPa. The hydromill also allows to correct any deviation from the vertical while excavating, in order cut competent.

The special diaphragm wall construction sequence by hydromill and primary-secondary panels overlapping ensure higher chances of watertight joints than conventional grabs.

With the hydromill technology it is possible to excavate diaphragms of a thickness of more than 2,000 mm at a depth exceeding 100-150 m.

Technology

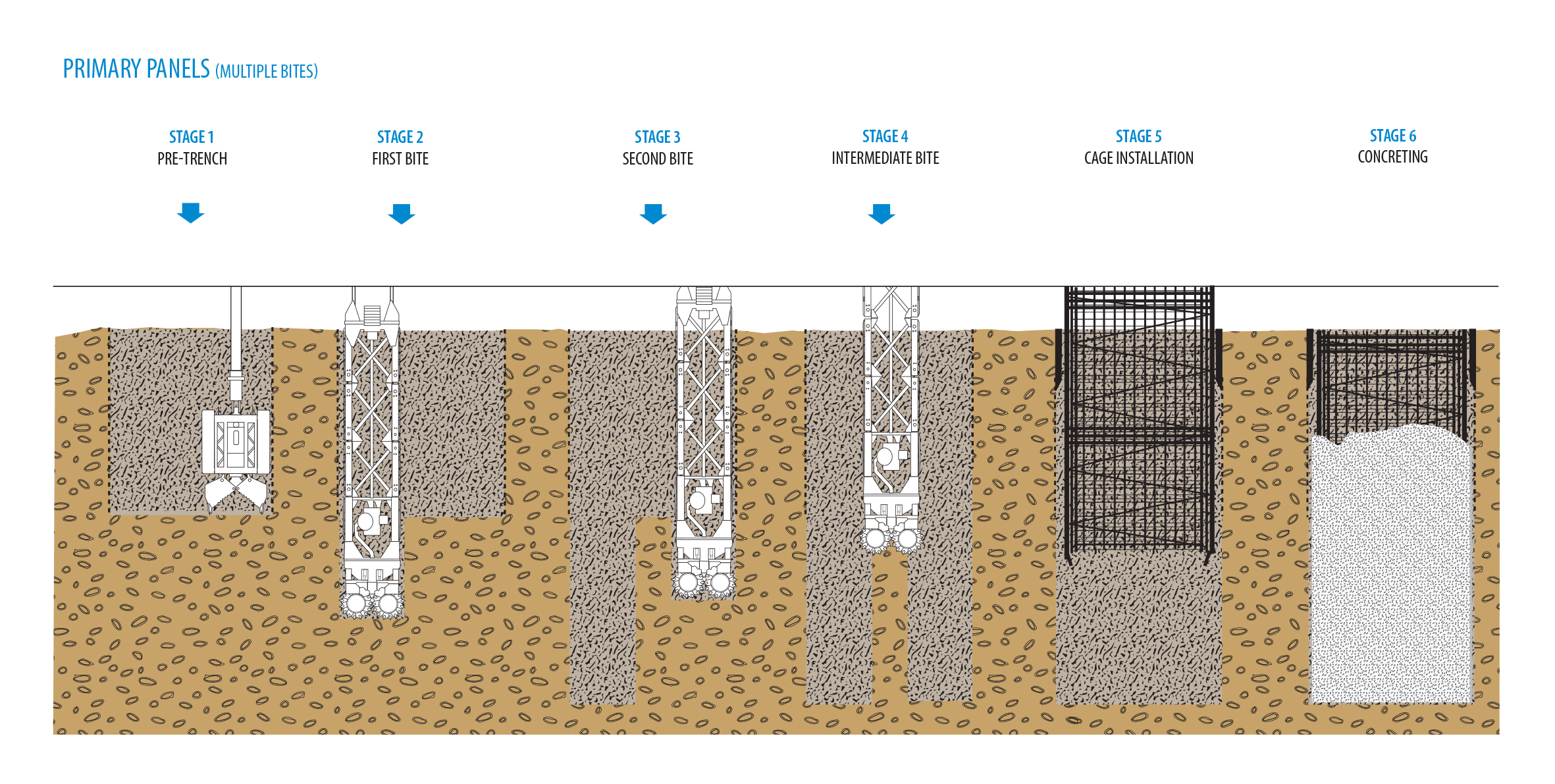

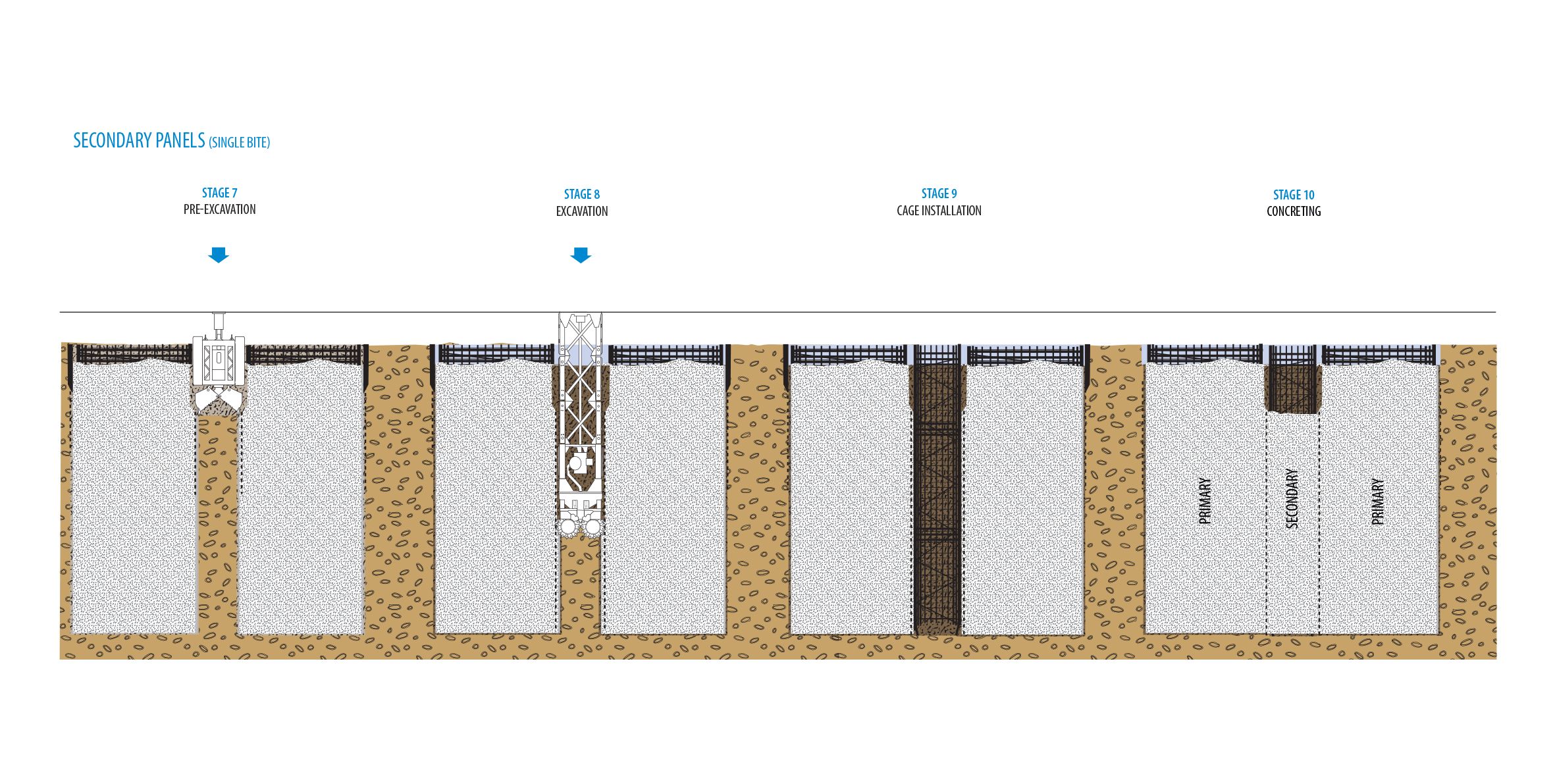

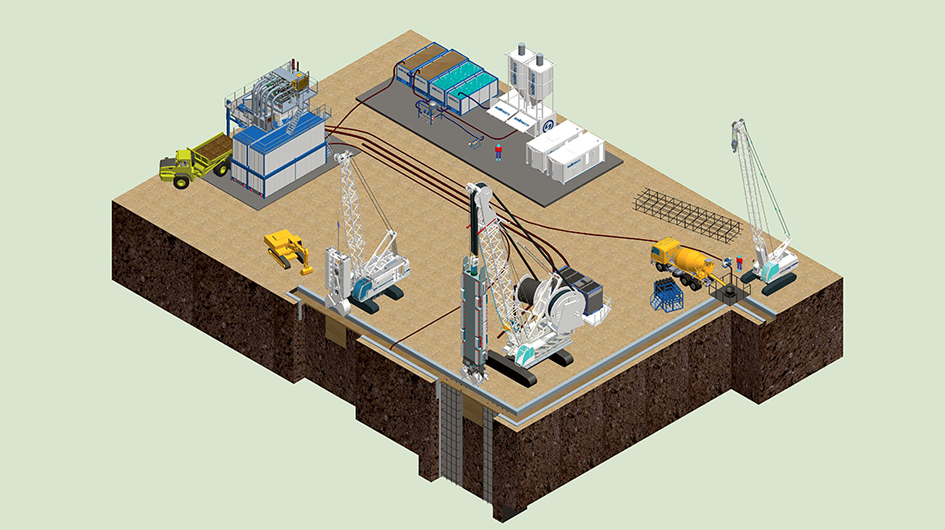

The diaphragm wall construction phases by hydromill are the following:

• site preparation

• construction of guide walls

• pre-trench excavation

• panel excavation

• slurry de-sanding

• installation of reinforcement cage

• concreting

The panels are divided into primary and secondary panels. The primary panels can be realized by either single or multiple bites.