Jet Grouting

Jet grouting improves soil mechanical and permeability properties by using high-speed jets of water/cement mixtures injection treatment.

Jet grouting can be advantageoudly in the following conditions:

• difficult logistic conditions

• confined spaces

• presence of obstacles to cross

• high-depth treatment with crossing of voids

Suitable soils

The jet grouting technique allows to improve a wide range of soil types. As it is based on soil erosion, soil erodibility is crucial to the final result. The more consistent the soil to be treated, the smaller the column diameter. Therefore, larger columns can be obtained in loose soft soils and smaller ones in cohesive soils.

Technology

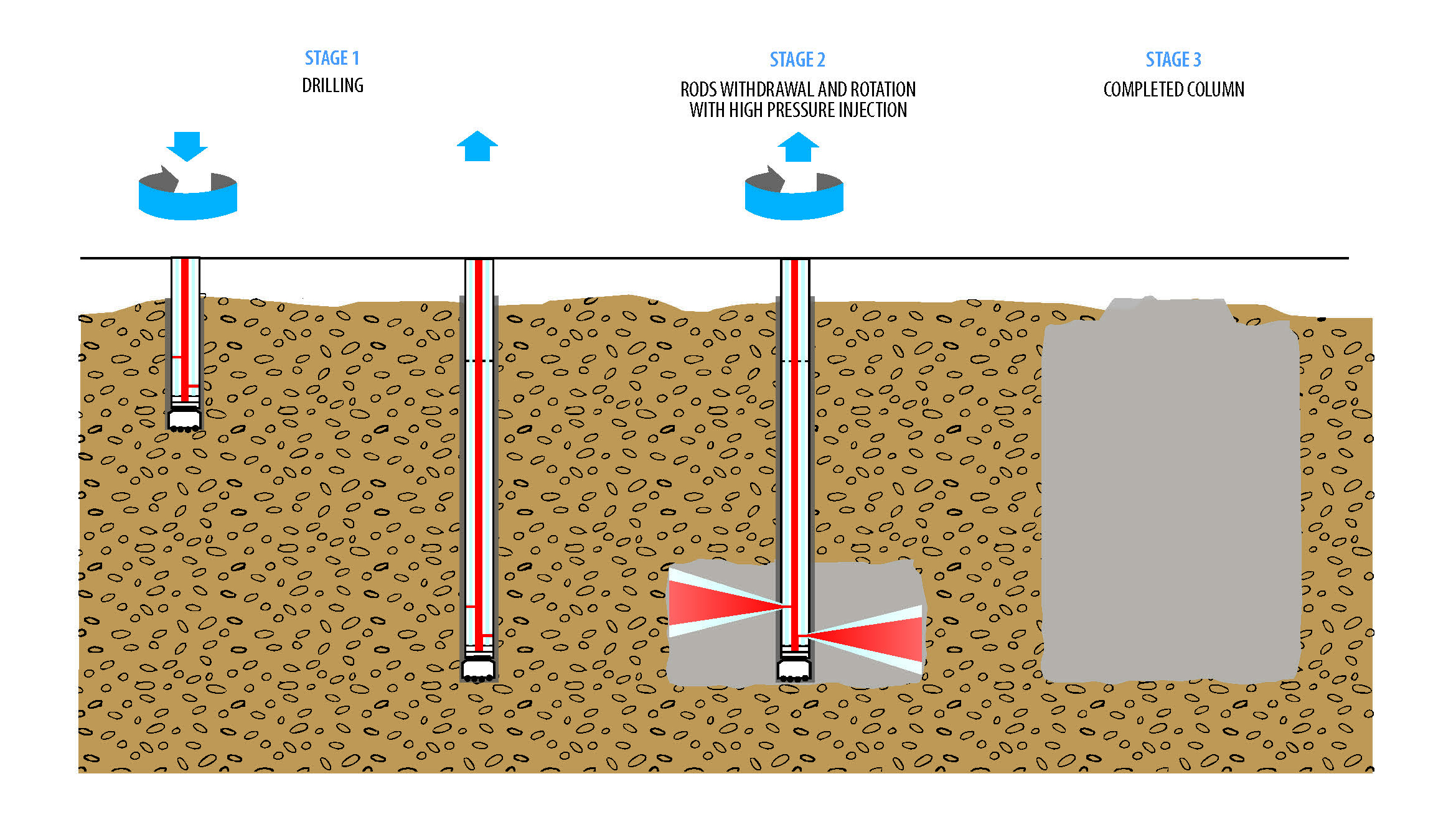

Consolidated elements – usually columns – are constructed using small-diameter drilling (100 to 140 mm), by means of light and easy to handle rigs. Moreover this technology allows to realize consolidated soil elements and overcome underground obstacles (foundations, blocks, etc.). Jet grouting is usually performed down to depths of 20- 30 m. However, special projects reaching 100 m-depth have also been realized. All jet grouting techniques envisage a preliminary phase of drilling, followed by extraction and rotation at preset values, and simultaneous pumping of the fluids at high pressure.

Depending on the number of fluids used, the European standard EN 12716 has identified three main techniques:

• Monofluid (TREVIJET T1): a water/cement mixture is injected to break up and simultaneously mix the soil in-situ. Diameters usually range from 0.4 to 1 m.

• Bifluid (TREVIJET T1/S): a combination of water/cement mix and air is injected to break up and simultaneously mix the soil in-situ. Diameters usually range from 0.8 to 2.5 m.

• Triple fluid (TREVIJET T2): a combined water/air jet is used to break up and partially remove the soil in-situ, whereas soil mixing is ensured by a lower water/cement injection.