Jamestown, Kentucky (US)

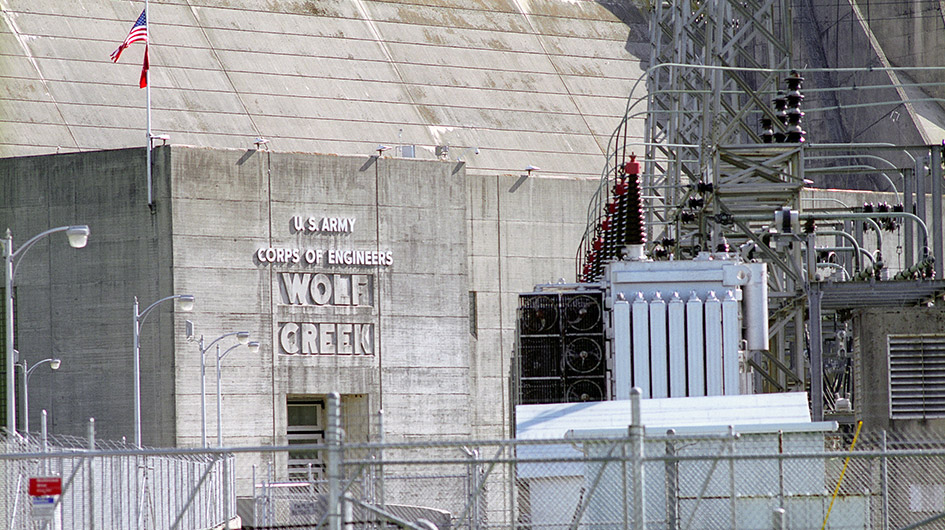

Wolf Creek Dam is on the Cumberland River in south central Kentucky. It provides hydropower, flood control, water supply, and water quality benefits for the Cumberland River system and surrounding region. Lake Cumberland, created by the dam, impounds 6,089,000 acre-feet at its maximum pool elevation of 760. It is the largest reservoir east of the Mississippi and the ninth largest in the United States.

In late January 2007, the USACE placed the dam under "high risk" for failure designation and launched a major, and ambitious, remediation program to bring the dam to a full operating condition.

| Owner | US Army Corps of Engineers |

| Contractor | TREVIICOS-Soletanche, JV |

This major rehabilitation program was awarded in 2008 to the TREVIICOS led joint venture, TREVIICOS-Soletanche, JV, for the construction of a 980,000 sqft concrete barrier. This 2-ft. wide concrete barrier wall has been built to depths exceeding 275 ft. under quality control measures that exceed by far the industry standards. Ground-breaking methods were developed for construction and quality control. Specialized equipment designed and built for this project was used to excavate through the embankment and into the rock foundation. Dam safety and risks associated with work inside an active high head dam were at the forefront of all decision-making.

The Corps and contractor teams were constantly monitoring and reacting to the dam’s response to construction activities. This required a robust QA/QC program and substantial upgrades to the existing instrumentation on the project After completion of the foundation drilling and grouting, a 6-ft. wide Protective Concrete Embankment Wall (PCEW) was installed in the dam’s embankment and into the foundation rock, using hydromill excavation to protect the embankment during subsequent secant pile and hydromill panel installation.

Once the PCEW is finished in one area, several technologies are utilized to install the barrier wall itself. Some of these technologies were successfully developed, by the TREVI Group, specifically for this project to become new breakthroughs in the foundation industry. Out of these new technologies, the Directional Drilling, used to guide the secant piles, which are installed with Reverse Circulation Drilling became the activity driving the project to an unprecedented level of quality.

Most of the barrier wall was installed with 1197 secant piles, creating 1196 joints totaling about 280,000 linear ft. Overall statistics showed the average wall thickness was 3.2 ft.

For the Combined Barrier Wall sections, built with a combination of piles and hydromill excavated panels, measurement statistics showed a minimum wall thickness of 2.6 ft, a maximum of 3.1 ft, and an average of 2.6 ft.

These extraordinary results were due to the techniques pioneered on this job for installing, steering, and measuring in real time the location of wall elements.

The concrete barrier wall, which is the main scope of this project, has been successfully completed on March 6, 2013, approximately 9 months ahead of schedule with outstanding quality and an impressive 1.3 million hours worked without a lost time injury.

Construction of a secant pile barrier wall utilizing the cased piles technique is ongoing on the downstream side of the dam.